The Balancer

One of the many options of using axial valves is to install them as anti-surge valves in rotary compressors in the liquefaction process to transform natural gas into LNG. To protect the compressors, anti-surge valves must open very quickly and let down the pressure at the outlet side. This is why the valves need to have a fast response while allowing for a high flow capacity and low-noise operation. The Type 3599 Axial Globe Valve has all these features.

All Standards approved

Ringo is API 6A certified for production and testing of chokes according to all Product Specification Levels: PSL1, PSL2, PSL3, PSL3G and PSL4 as well as for the two different Product Requirements: PR1 and PR2, depending on service and customer requirements. In addition, our chokes can be design and produce according to other different standards on request, such as ASME B16.34 or GOST.

Versatile in use

Different cage versions make the choke valves suitable for use in a wide variety of applications, such as uncritical, anti-cavitation, low-noise or even zero-noise service.

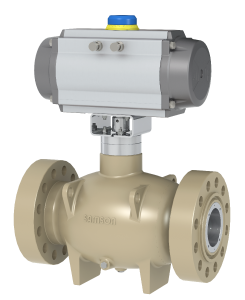

Modularity from the body till the actuator

Based on your specific application requirements we offer our choke valves with serveral body, bonnet and actuator types. This leads to a perfect fitting product for all your needs.

Prime features

Multi-stage Solutions

-

MULTISTEP™

Multistaged trim for small Cv values, normally used for choke valves of small sizes. In addition can be added to other plug types to provide high rangeability (up to 1:200) and multi-stage effect for start up conditions at low stroke, where other common multi-stage system has no effect.

-

CAVLESS™

CAVLESS™ cage has a double drilled series of radial holes, which provides a nozzle effect. The design can control the location of the vena-contracta and therefore control the location where cavitation occurs. When the plug is throtling a number of nozzles will be uncovered and the resulting jet stream of cavitation liquid will be directed into the cage center. This diverts the harmful effects of cavitation away from the plug and cage. Only available in Flow Over the seat configuration.

-

MULTICYL™

With our MULTICYL™ cage the fluid goes through a staged pressure reduction process, utilizing as many stages as necessary to keep pressure drop under critical values. We have the expertise to calculate, design and manufacture the MULTICYL TM trim with the necessary number of stages to have xT and Fl as higher as required by process conditions.

-

CROSSTEP™

CROSSTEP™ design behaves as a multistep pressure reducing cage with multidisc stack construction, the crossings being the equivalent of the restrictions-expansions with the advantage of a lower pressure recovery. The cross-sectional area of the channels, the number of channels per disc, the impinging angle at every crossing and the number of crossings, are calculated to best suit every particular set of conditions.

These industries work with our solutions