The Reliable

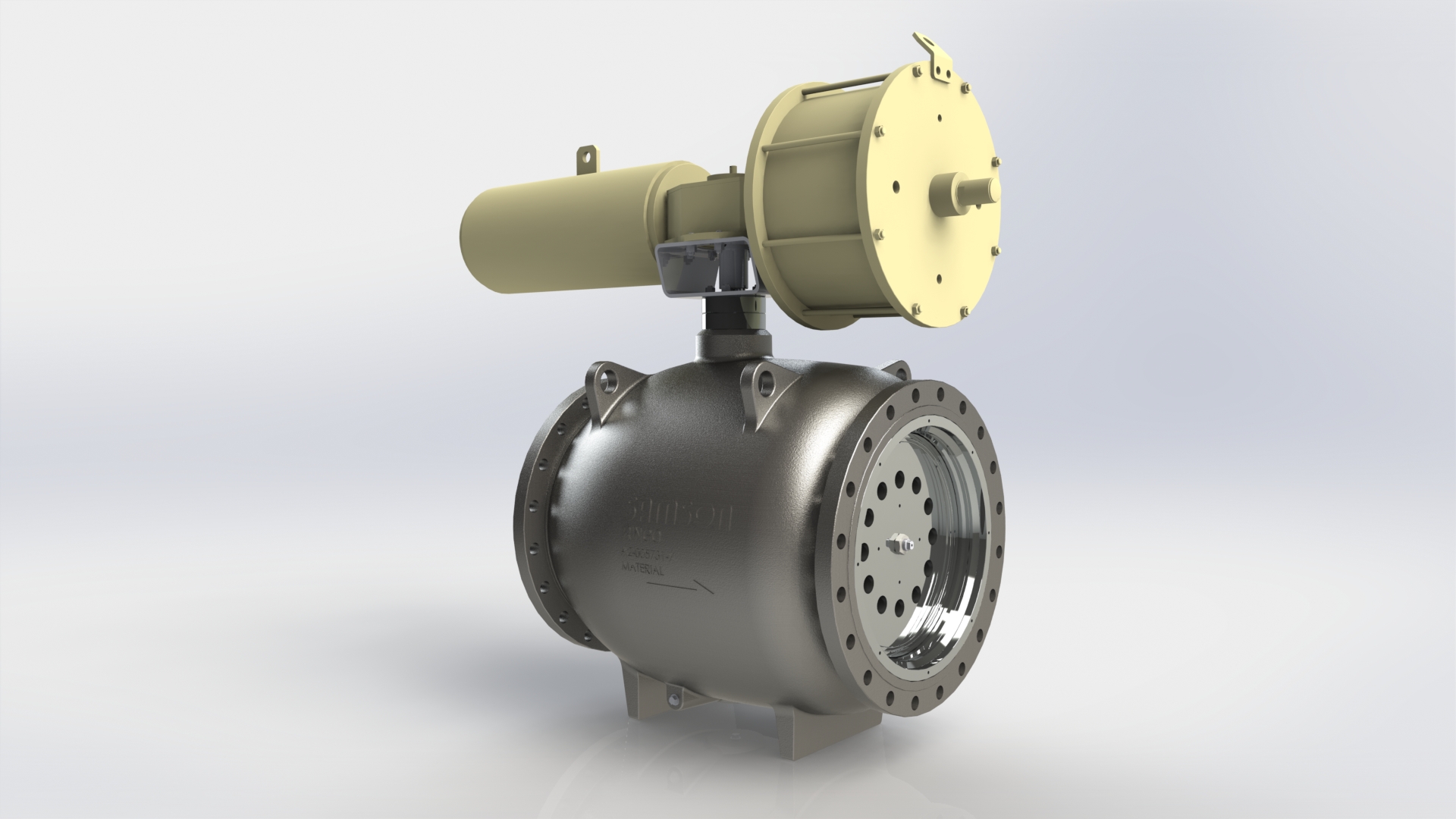

One of the many options of using axial valves is to install them as anti-surge valves in rotary compressors in the liquefaction process to transform natural gas into LNG. To protect the compressors, anti-surge valves must open very quickly and let down the pressure at the outlet side. This is why the valves need to have a fast response while allowing for a high flow capacity and low-noise operation. The Type 3599 Axial Globe Valve has all these features.

Highest control accuracy

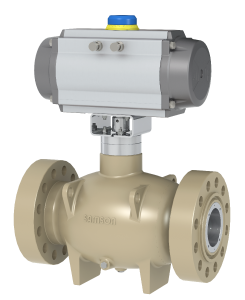

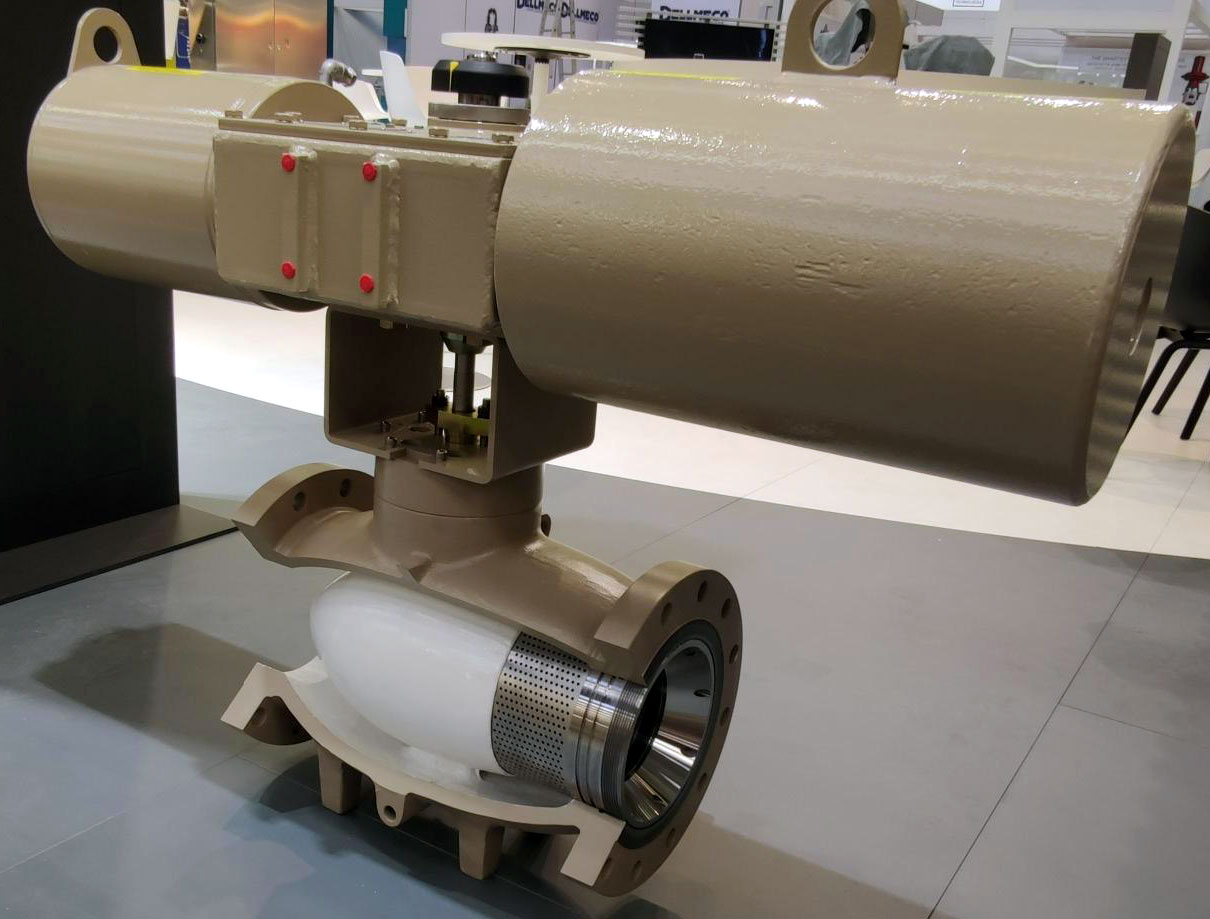

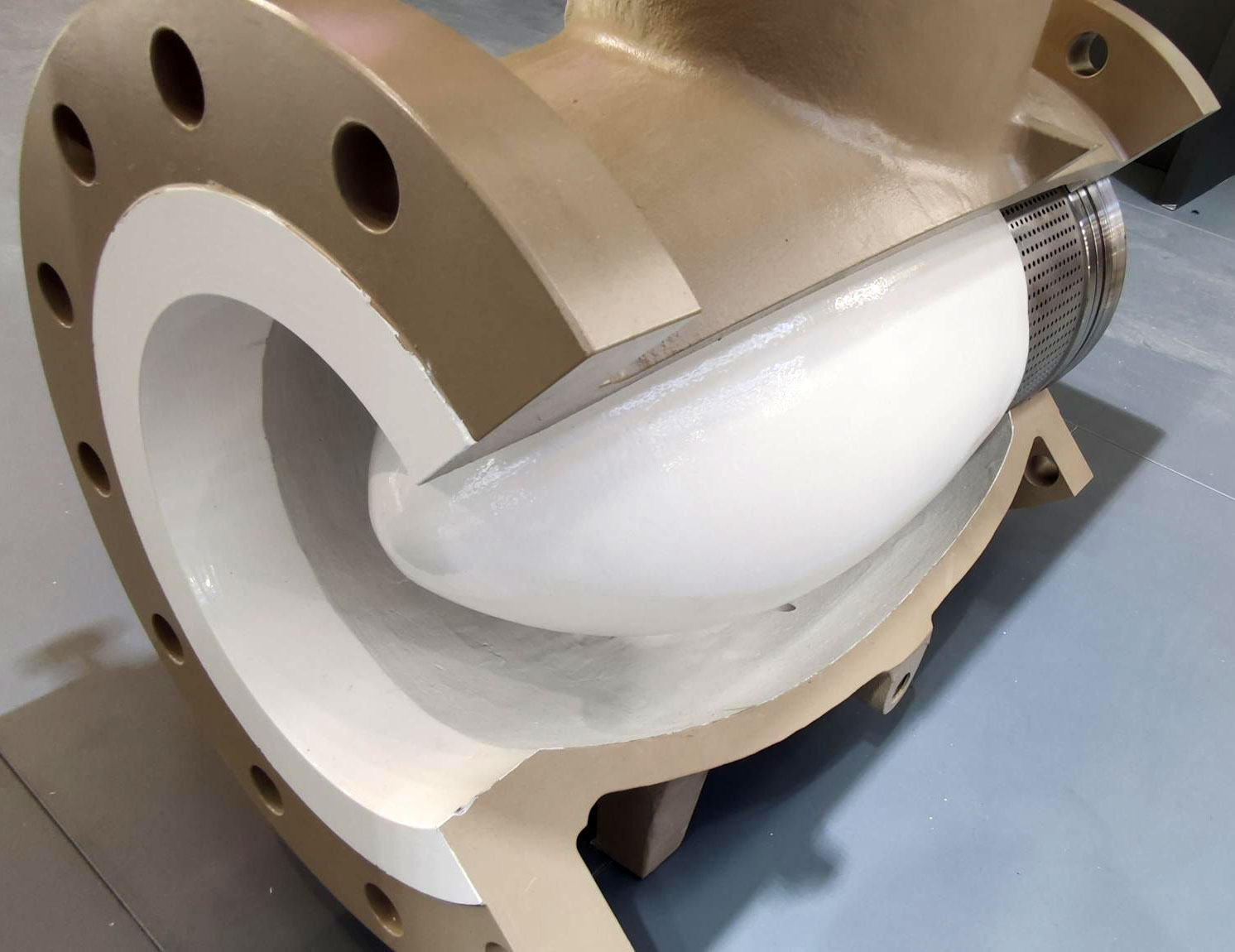

The Type 3599 Globe Valve has an axial flow path. The integrated drive mechanism, which is protected from the process medium, converts the rotary motion into a linear motion and provides maximum thrust for a high control accuracy.

Versatile in use

Different cage versions make the axial globe valves suitable for use in a wide variety of applications, such as uncritical, anti-cavitation, low-noise or even zero-noise service.

Wide actuator selection

Selecting the right actuator for the axial globe valves is very easy. Thanks to the integrated drive mechanism and the pressure-balanced plug, the full range of rotary actuators having a rated opening angle of 90° can be mounted.

Prime features

ACHEMA 2022

Product range for liquefied natural gas

-

Extraction and liquefaction

Natural gas is refined and liquefied once it has been extracted from the ground. During liquefaction, it is cooled down to approx. –160 °C. Liquefied natural gas (LNG) has a considerably lower volume than its gaseous counterpart, which makes it better to transport and store. SAMSON has the following products in store for the extraction and liquefaction of natural gas: wellhead valves, amine dump valves, anti-surge valves and cryogenic valves.

-

LNG as ship fuel

Stricter emission standards in ocean shipping make it necessary to convert ship engines from heavy fuel oil (HFO) to LNG. This is done to reduce the greenhouse gas emissions of ships to meet the defined emission targets. The SAMSON product range includes suitable blow-off, bypass, pressure relief and LNG shut-off valves.

-

Transport

Usually, LNG is transported by LNG tanker ships. These tankers are specifically designed to handle and transport the liquefied gas. They are fitted with cryogenic valves, tanker loading valves and blow-off valves by SAMSON.

-

Storage and regasification

LNG is unloaded at onshore or floating LNG terminals where it is heated up to convert it from the liquid to the gaseous state. This regasification is necessary to feed the natural gas into existing gas tanks and distribution networks. SAMSON supplies suitable expansion, high-pressure, metering and ESD valves for these applications.

These industries work with our solutions