The Unbreakable

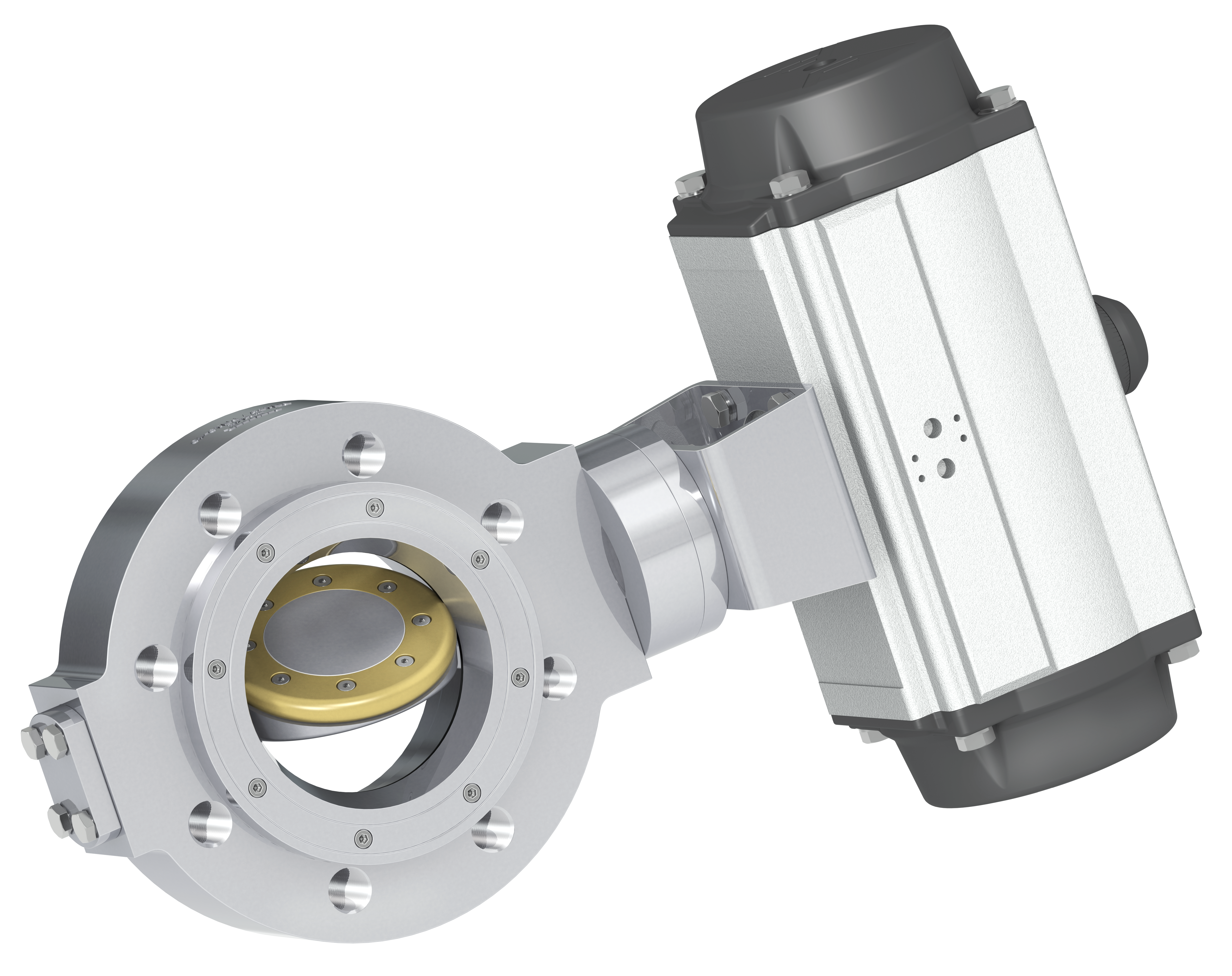

The pressure swing adsorption process can produce hydrogen of up to 99.99 % purity. The process requires extremely rugged valves that can operate reliably even when faced with fluctuating conditions, such as a high number of switching cycles, long idle times and frequent load changes. The PSA butterfly valves by SAMSON PFEIFFER are specially engineered to tackle the challenges posed by pressure swing adsorption and are designed to be extremely resistant to wear.

Rugged engineering

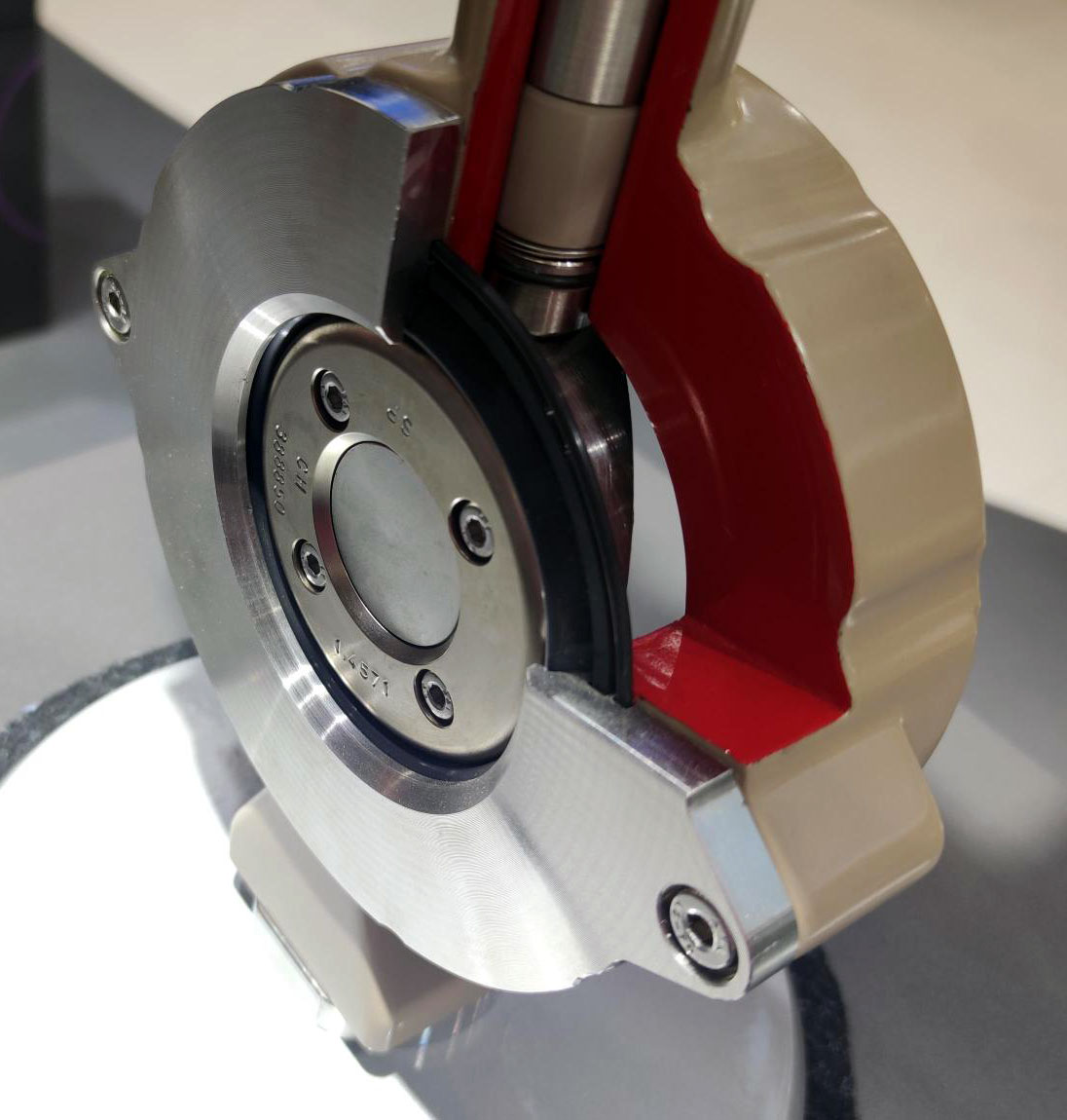

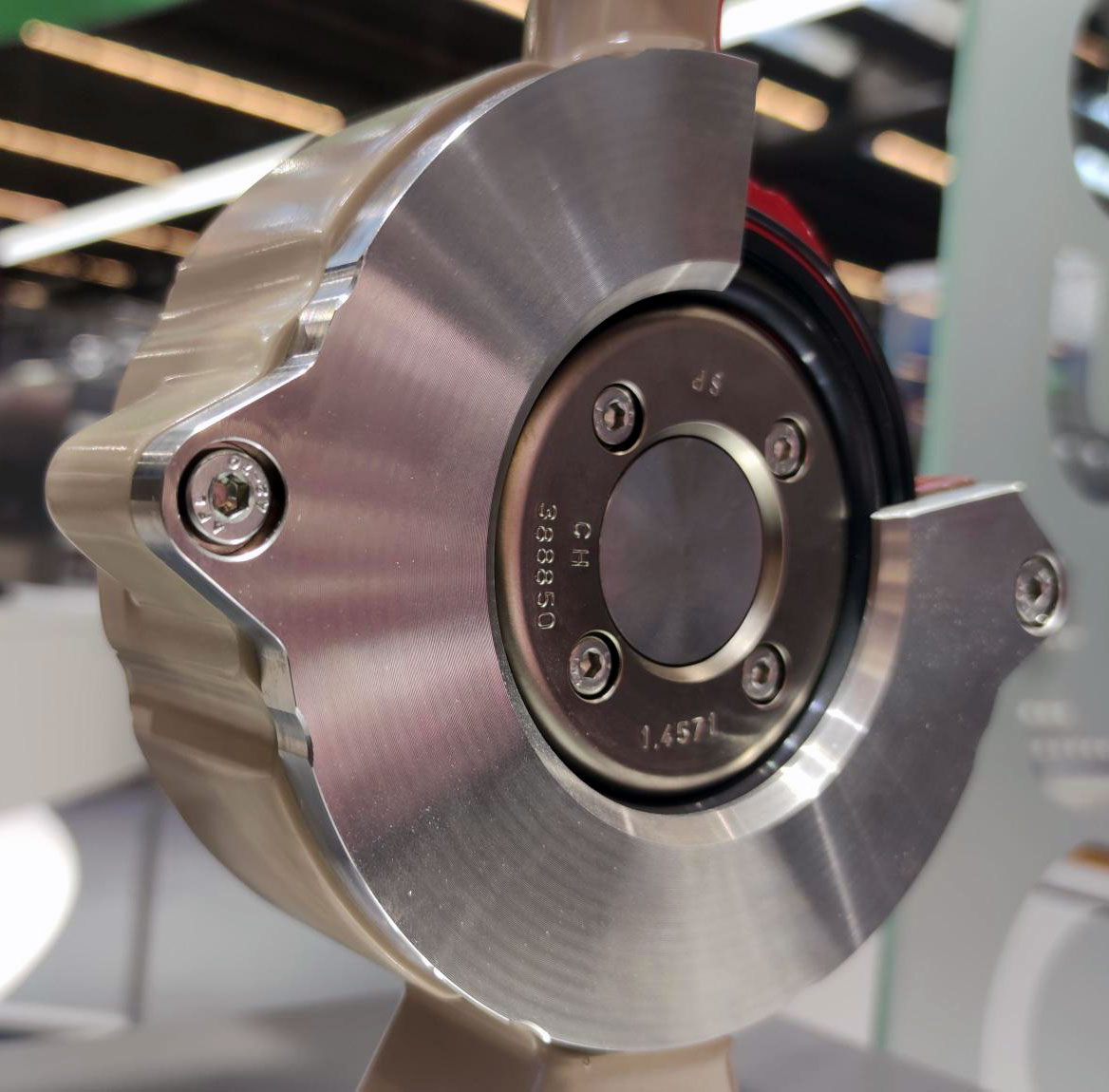

The heavy-duty design with a solid valve body and double-eccentric disk makes the high-performance butterfly valve extremely rugged. Despite long service intervals, the valves isolate and control the medium flow reliably over their entire service life.

Leak tight

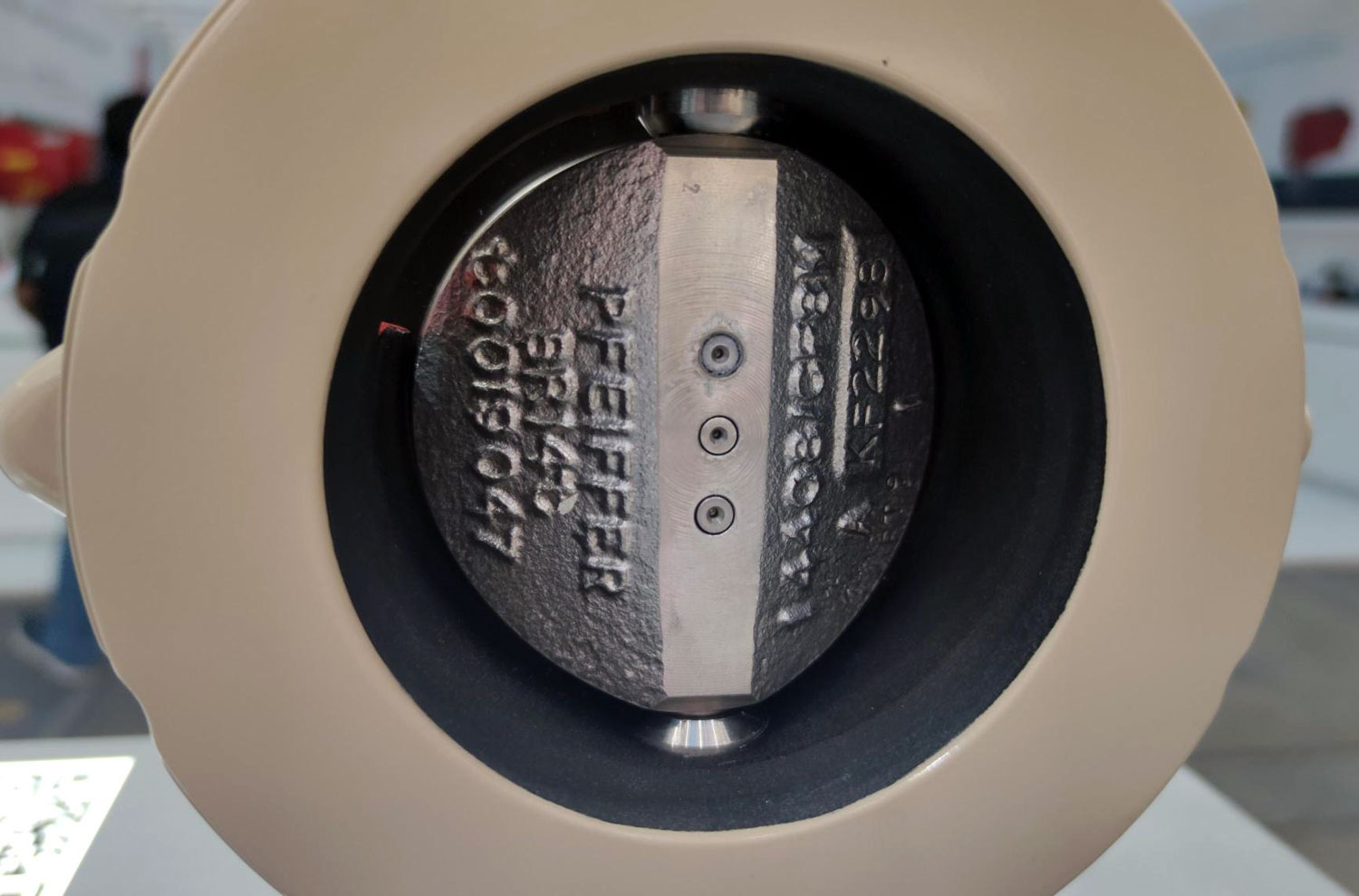

A V-ring packing loaded by disk springs ensures that the valves remain leak tight. Bidirectional gas-tight shut-off between the seat and disk is achieved by a special elastomer seat ring used in combination with a coated disk ring.

Medium flow in both directions

The valves can function as either control or shut-off butterfly valves depending on the direction of flow. When functioning as a control valve, the medium flow lifts the butterfly disk slightly out of the seat. This helps reduce the initial breakaway torque.

Type 14p PSA Control and Shut-off Butterfly Valve

ACHEMA 2022

Services provided throughout the entire life cycle

-

Customer inquiry

As soon as we receive your specifications, the customized engineering process starts.

-

Planning and tendering

During sizing, we take into account the various conditions and requirements in the plants to provide you with the best solution for your specific control task.

-

Production and quality control

After tendering has been completed, production of the components starts, accompanied by continuous quality control.

-

Start-up

Our after-sales service staff applies its extensive specialized know-how of plants and devices to assist you with mounting and start-up. Our tightly meshed global service network guarantees high availability and short response times.

-

After-sales service

Our after-sales service staff can support you in many ways: troubleshooting in the plant, spare parts management, servicing, re-engineering or plant optimization.

These industries work with our solutions